TERRACLAD® RAINSCREEN

Boston Valley Terra Cotta’s ceramic rain screen cladding system provides benefits above and beyond conventional masonry cavity wall systems. In addition to the durability and ease of maintenance inherent to any ceramic cladding, the TerraClad® system incorporates ship-lapped open joints that shield the structural wall from wind-driven rain and snow while also ventilating the airspace to mitigate mold and mildew growth. Gaskets and isolators provide a snug fit between panels and the framing system to prevent wind-induced rattle and allow for movement of the aluminum framing system due to thermal expansion. Beyond the functionality of the system, the plasticity of terra cotta offers profile opportunities to designers not available in alternate rain screen cladding materials.

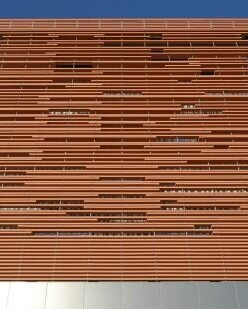

TERRACLAD® SUNSHADE

Boston Valley offers sunshade devices as part of our TerraClad® product line. They can be used in combination with the rain screen system or as a standalone feature. A true marriage of form and function, these sunshade devices aid in reduction of glare and help to shield occupants from the sun similar to traditional blinds. TerraClad® sunshade devices provide designers with another component with which to create a unique, modern building facade.

TERRA COTTA MASONRY

Even after thousands of years of building and the introduction of modern techniques and new materials, terra cotta continues to be the cladding material of choice for many designers. Few if any materials surpass terra cotta in its longevity, sustainability, malleability, UV resistance, ability to withstand severe climates, and finally the possibilities in texture and finish that it can offer.

TERRAPRECAST®

For decades architectural designs have involved embedding a facing material in precast concrete panels. Boston Valley Terra Cotta is now offering our TerraPreCast® product line as a finishing material for precast concrete. A minimum 30mm solid terra cotta veneer as well as units with custom profiles can be embedded in large precast units. The dovetail profile on the backside of the veneer provides additional surface area for the concrete to adhere to the terra cotta, ensuring a high-strength bond between the two products. This system is ideal for those needing the strength and durability of precast concrete construction, but desiring the myriad of options available in both profile and finish offered by terra cotta. TerraPreCast® Technical Data Sheet

UNITIZED

Unitized systems are a segment of curtain wall construction that takes assembly off-site and into a controlled factory setting: giving the advantages of speed of installation, lower field labor costs, and quality control. While terra cotta’s materiality and wide array of design options contribute to its popularity in architectural facades throughout history, its malleability of form and profile makes it just as suited for today’s unitized systems and high performance facades.